Insulation of lightweight buildings with closed-cell polyurethane foam

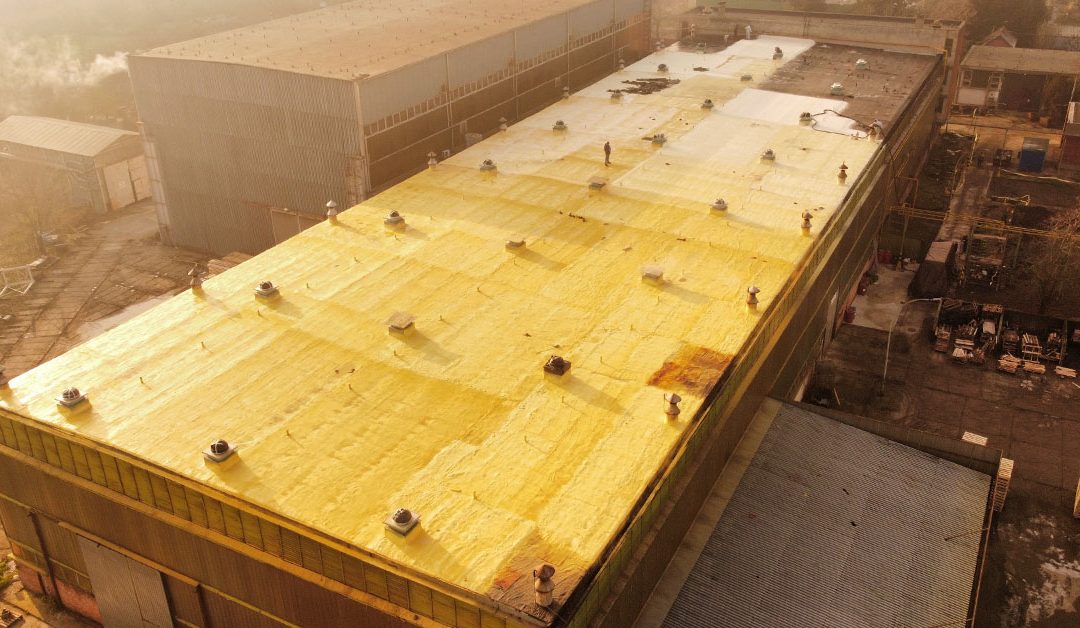

We insulated a lightweight building in Nyíregyháza!

During the planning and construction of industrial properties and lightweight buildings, many challenges must be faced. These include ensuring effective thermal insulation, minimizing heat loss caused by metal structures and implementing protection against moisture. Traditional solutions often do not fully meet these expectations, however, a new technology – closed-cell polyurethane foam – can revolutionize the insulation of halls and industrial buildings.

The problem

Owners of lightweight buildings, including halls and industrial properties, often face serious insulation problems. High heating costs must be expected due to thermal bridges and heat loss caused by metal structures. In addition, in many cases, the moisture protection is not adequate, and completely uninsulated trapezoidal roofs and side walls can cause serious problems with getting wet. Condensation can result in further complications, which can lead to damage to the building and the products stored in it.

The Solution: insulation of lightweight buildings with closed-cell Polyurethane Foam

There is an effective solution to the insulation challenges of industrial buildings: closed-cell polyurethane foam. This advanced insulation material has properties that allow lightweight buildings to effectively cope with the problems of heat loss, moisture and condensation.

1. Excellent Thermal Insulation

Closed-cell polyurethane foam has an extremely high thermal insulation capacity. Incorporating foam into roofs, walls and floors makes it possible to effectively minimize heat loss. In this way, the heating and cooling costs can be reduced, which can result in significant savings in the long-term in the operation of the lightweight building.

2. Moisture protection

Closed-cell polyurethane foam has waterproof properties due to its extremely dense structure. This allows the foam to serve not only as thermal insulation, but also as effective moisture protection. Wetting problems can be prevented even with the minimum thickness, which protects the structure and durability of the building in the long term.

3. Elimination of vapor precipitation

The closed-cell polyurethane foam seals the structure of the building airtight. This results in cold and warm air not mixing, which minimizes the possibility of condensation. Humidity control becomes much more effective, which increases the healthiness and comfort of the indoor environment.

The Advantages

The use of closed-cell polyurethane foam has many advantages during the insulation of industrial properties and lightweight buildings. These include:

- Savings: Excellent thermal insulation reduces heating and cooling costs.

- Structural protection: Moisture protection preserves the durability and integrity of the building structure.

- Comfort and health: By minimizing condensation, it results in a better indoor climate and a healthier environment.

- Quick and easy installation: The foam is easy to attach and adheres evenly to each layer, filling the gaps and sealing them airtight.

Conclusion

Insulation of industrial properties and lightweight buildings is a key factor for efficient operation and maintenance. Traditional solutions often cannot fully meet expectations, however, closed-cell polyurethane foam allows us to solve the problems of thermal insulation, moisture protection and condensation at the same time. This improves the building's energy efficiency and internal environment, contributing to sustainable and comfortable operation.

You can read about lightweight structure insulation here: link

Our client's website: link