Trapezoidal plate insulation

Unbeatable solutions for lightweight buildings. Heat and water insulation of trapezoidal sheets quickly, in one step - with closed-cell dispersed purfoam.

Material:

Closed cell

Progress:

300 m2/day

Thickness:

5+ cm

Density:

55 kg/m3

Trapezoidal sheet insulation with PU foam

Thermal insulation. Most domestic lightweight buildings made of trapezoidal sheets are not insulated and/or get wet. The closed-cell purfoam kprovides excellent thermal insulation. Heating and cooling costs can be significantly reduced with it, and the comfort of the building occupants will improve, as temperature fluctuations will disappear.

Soaking. Due to the dilation, the foam sprinkled on the trapezoidal plate stops the water. Spray foam can adequately cover even the smallest gaps, such as gaps between plates or gaps around plate fixing screws. The hard material strengthens the structure of the building made of trapezoidal sheet, the elements will not move, no gaps will form, the roof will be walkable.

Vapor deposition. Large temperature differences are encountered on the walls of uninsulated buildings (in winter, the warm indoor air comes into contact with the cold surface), condensation appears. Dripping steam is not only annoying, but can also cause damage to the building or in the crops and machines stored in it. Since there are no large temperature differences on the insulated surfaces, the condensation problem will not return either.

Insulation of lightweight buildings - purhab ADVANTAGES

Shape tracking, recording

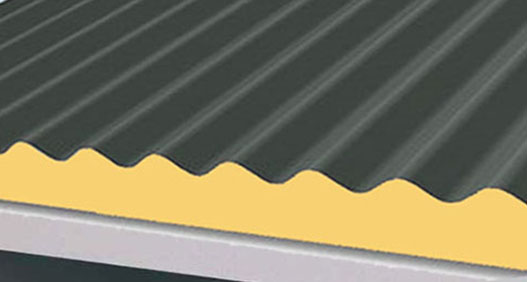

The trapezoidal sheet surfaces are special, their insulation with traditional materials is very problematic due to the following shape. Purfoam is the only perfect way to cover the ribs of the trapeze, protecting it against heat and water with a continuous layer.

In the case of other insulations, fixing or the layer order is also more complicated, as other materials do not guarantee heat and water insulation in one step! Save yourself from mistakes - choose the one-size-fits-all solution!

The foam follows the expansion movements of the building, you don't have to worry about cracks appearing on the insulation. If we insulate from the outside and the sun does not reach the trapezoidal plate, the thermal expansion of the building can be eliminated from the start.

- Will 1000 m2 per daywe insulate it! Fast implementation is a really big advantage where the time factor is important.

- Spreading foam insulation does not involve upheaval. There is no waste after work, no delivery costs.

- The insulation is moisture and mold resistant. Easy to use, even can also be cleaned with a high pressure washer.

The closed-cell foam is a strong, hard layer of the building also significantly strengthens it statically. The closed-cell foam weighing 45-55 kg/m3 is strong, hard, walkable, yet means a minimal weight load.

The closed-cell foam is excellent, with a B2 fire protection classification - it does not feed the fire.

Trapezoidal plate insulation from the outside

What is a table setting?

The big advantage of foam insulation is that it completely takes the shape of the trapezoidal sheet, which is why it will be wavy. The thicker the layer, the more we can smooth out the waves caused by trapezoids. Covering a trapezoid plate requires more material than a flat surface, we always count on a tablecloth when surveying. This usually means 15-25 % on top of the base area.

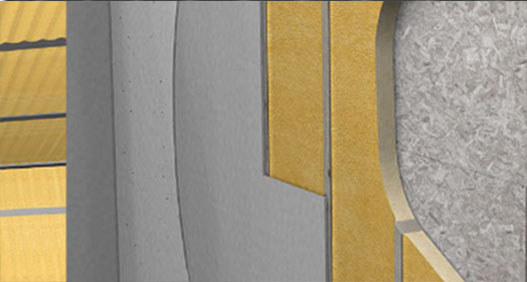

Sendics panel vs. scattering insulation

Building with sandwich panels is popular these days. The insulating material in the sandwich panel is the same, but here you buy it between two steel plates (rebars). If you already have an uninsulated trapezoidal sheet surface, it is cheaper and more practical to choose subsequent, spray insulation, since the cost of dismantling and transporting the old structure, the purchase price of the sandwich panel, and fixing it is several times that of spray insulation.

In the case of new buildings, we often cannot compete with sandwich panels due to aesthetics. In terms of costs, the spray technology is also more economical in this case, since the customer can save a layer of corrugated board (with today's steel prices, this is a huge amount for a hall). In the most important area, spread insulation produced on site, without gaps and joints, always wins: the sandwich panel elements are not continuous. Defects will appear over time due to dilatation, water may enter the building during joints and fixing screws, and due to the movement of the plates, the insulation will not be completely airtight.

Why with us?

We work continuously with the largest capacity, 10 trucks and 25 specialists, all over the country. We come to work with the most modern, new tools.

We work with qualified, premium quality raw materials. We buy big quantities from our suppliers, so we can work on lower prices than our competitors.

You can take the guarantee for our work seriously: we have been insulating for more than 12 years.

We don't know anything impossible. Unique, problematic projects are also realized with us. Insulation is the heart of our experienced team.

If you are interested, we will assess your property free of charge.

Trapezoid plate references

Hotel insulation

"Hotel Insulation" - Innovations in the Panoráma Hotel, Köszeg Insulation not only improves the habitability of houses, but can also result in significant savings in the long term in terms of energy bills. The Panoráma Hotel burned down a few years ago. The owner is the old...

Trapezoid plate insulation from the bottom side

Slab insulation from below Another reference for slab insulation from below. Lightweight buildings often suffer from condensation problems and high heating costs, especially if they are not properly insulated. We recently solved a...

Insulation of lightweight buildings

Insulation of lightweight buildings We insulated a lightweight building in Nyíregyháza with closed-cell polyurethane foam! During the planning and construction of industrial properties and lightweight buildings, many challenges must be faced. These include...

Applications

Request an offer!