Polyurethane foam

What is closed-cell and open-cell purfoam good for?

When do you need UV protection? Read more below!

Our products

Closed-cell foam

Open cell foam

Excellent heat and sound insulation, for filling large hollow spaces

Polyurea UV protection

What is polyurethane insulation?

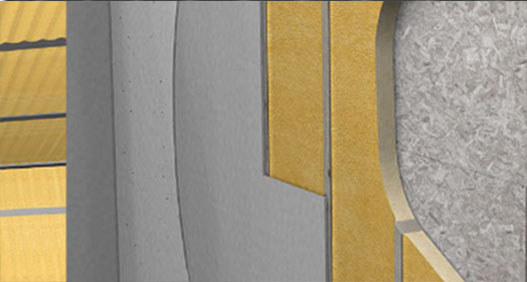

Sprayed polyurethane is a plastic applied by spraying, which forms a continuous insulation, an airtight barrier on walls, roofs, main roofs, tanks, etc. Thanks to the technology, the insulation is completely customized: we create the insulation at the work site by mixing and reacting the liquid components. After mixing, the liquids react with each other very quickly, they solidify in just a few seconds during spectacular swelling. Purfoam provides excellent insulation, seals joints and can form a moisture and vapor barrier layer.

The dispersed polyurethane foam is heat-hardening cellular plastic insulation, its two main components are polyol and isocyanate. During the reaction, the two substances release heat, and within a few seconds a solid foam is formed, which is only sticky for a very short time.

Thermal conductivity

How much heat passes through the 1 meter thick, 1 square meter surface of the given material in 1 second, if the temperature difference between outside and inside is 1 degree Celsius. Its unit is Watt/meter*Kelvin. It is indicated by the Greek symbol lambda, the smaller the better the thermal insulation material.

Thermal insulation ability

The thermal resistance shows the resistance of the given material to one degree of temperature. It is also called the R value, the higher it is, the better the thermal insulation material.

Use of units of measure

The lambda value of closed-cell foam is 0.023 Watt/meter*Kelvin, while that of open-cell foam is 0.034 Watt/meter*Kelvin.

Mineral wool (0.042-0.044), glass wool (0.058).

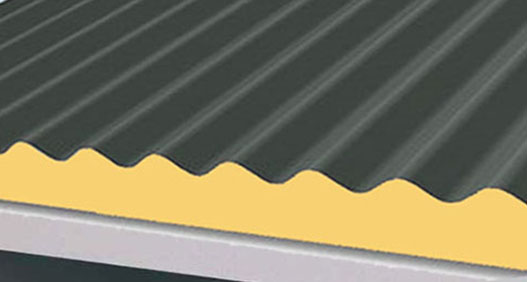

Closed-cell foam

Closed-cell foam is the best thermal insulation available today, the unique advantage of which is that it also provides 100% waterproofing to the insulated building. Its surface is strong, compact and walkable. Our machines installed in our trucks mix the two liquid components, which we apply to the surface through a heated hose. After being blown out, the substance changes from a liquid to a solid state in a few seconds, while it swells to forty times its original volume. The structure of closed-cell foam has a tight cell structure, it is stiffer and stronger than open-cell foam, so it is also suitable for insulating slabs, flat roofs, and terraces. It can be used on any construction materials used today.

Much denser than open cell insulation, it is not easy to remove from the surface. It forms a much harder layer than open cell foam. Closed-cell material is more expensive, but performs much better.

- lambda value is 0.021-0.022.

- load capacity: 250 kPa

- density 35-55 kg/m3

- fire protection: B2 self-extinguishing

- packaging: 200 l

- flat roofs

- attic/ high ceilings

- sheds, stables

- warehouses, halls

- pipes, tanks, containers

- waterproof, airtight

- the best thermal insulation available

- walkable, rigid structure

- gap-free: fills all cracks

- can be used on all surfaces

Open cell foam

This type is very light and can be easily disassembled by hand. Open cells allow water vapor to enter the structure, which wets the insulation. Open-cell polyurethane foam is a good sound and heat insulator, but it is important to point out that it does not provide waterproofing. It fills the spaces and surfaces you want to insulate in a form-following, gap-free manner.

The technology is the same as for the closed-cell product: a liquid substance is sprayed onto the surface from the mixer on the truck through a heated hose. This material solidifies in the same way, in just a few seconds, but the open-cell foam swells more spectacularly, about a hundred times. Similar to the closed-cell product, the foam-like insulation is also airtight.

- Material density: 8-10kg/m3

- Thermal conductivity factor: 0.035W/mK

(lambda value) - Fire protection classification: self-extinguishing, B2

classification

- attic installation

- slab structure

- indoor side wall

- exterior facades

- other old spaces

- excellent thermal insulation

- gap-free

- sticks strongly

- it doesn't collapse

- efficient filling of larger spaces

Polyurea UV protection

If the closed-cell foam is used outside the building, the insulation must be protected from the harmful effects of the sun. We recommend a special synthetic resin for this. UV coating solutions can be used valso as a water-blocking coating and corrosion protection. The UV protective layer forms a perfect gap-sealing, continuous, durable waterproof surface without seams or expansion. The versatile use of UV protection is due to its waterproof, wear-resistant, non-slip, flexible yet high hardness properties. The special two-component reactor heats the insulating material, which enters the spray gun through heated pipes and is then blown onto the surface at a pressure of 240 bar. After application, the material solidifies in a few seconds and reaches its perfect and final physical and chemical state in 24 hours.

- insulation of roofs and slate roofs

- UV protection of polyurethane foams

- internal insulation of pools

- truck flatbeds

- quick and easy application

- fills in the gaps

- in addition to waterproofing, UV protection

- flexible, does not crack

Preparation

Before the insulation, we consult with our customers about the related construction work in order to avoid damage to the insulation later. If, for example, you want to install solar panels on the flat roof, it is worth fixing their support legs before the insulation. If you plan to cover the insulated side wall or roof with plasterboard, it is worth placing the support brackets before the insulation. When insulating the socket, the fittings and pipes must be in place so that they do not have to be carved into the finished insulation, thus damaging the seamless insulation.

It is also important to discuss the surfaces to be protected in advance. During the preparation of the spray insulation, small particles of foam circulate in the air. Windows, doors, exterior parts of the building, nearby landmarks, and cars are all exposed to danger. The best solution is to cover nearby objects. Of course, for internal work, this risk is small, or covering is much simpler. When working outdoors, the direction of the wind must be taken into account before each blow. In excessively windy conditions, we stop outdoor work.

Protective equipment

Airway protection. The most important thing is to use the right protective mask. During the spraying, we ask our customers to leave the work area.

Eye protection. Appropriate eye protection protects the eyes from splashes of liquid components (e.g. during accidental spraying of reactive foam). Those performing the work and those checking it can protect themselves with goggles combined with a protective mask.

Clothing. If there is a possibility of direct contact with polyurethane components, wear suitable protective clothing. It is recommended to wear disposable overalls so that the spray does not come into contact with the skin and clothing. Always wash non-disposable clothing before wearing it again.

Glove. Safety gloves provide adequate protection. Pay attention to the size! Gloves that are too big or too small may not provide the user with adequate protection.

First aid

Health risks only occur during insulation. Polyurethane foam, once properly installed and cured, is NOT HAZARDOUS. It is therefore important that the persons in the work area wear appropriate protective equipment during work. Inhalation of the ingredients or contact with the skin can have harmful effects on the skin, eyes and lungs. into a wound. If you have come into contact with the substance, do not treat it lightly - seek medical help immediately.

Inhalation: Avoid mixing the components or inhaling the gases produced when the foam swells! If you see someone without a protective mask in the work area, warn them immediately and escort them to a place with fresh air. A high concentration of foaming agent (component B) can reduce the concentration of oxygen available for breathing. If the substance has been inhaled, symptoms may worsen several hours after inhalation.

Skin Contact: If you come in contact with chemicals containing the ingredients, shower or splash the affected area with water to clean the skin, then wash again with soap and water. Corn oil or propylene glycol may be more effective at removal than water. Remove contaminated clothing. If you have cut yourself during contact, seek emergency care immediately, as the chemical may have entered the bloodstream through the wound.

Eye contact: If the chemical gets into the eyes, flush the eyes with plenty of lukewarm water for at least 15 minutes. Get medical help as soon as possible.

Ingestion: If SPF chemical is swallowed, do not induce vomiting. Seek professional medical attention immediately.

Applications

Request an offer!